Understanding the key differences between jaw crusher machine types is essential for anyone involved in mining or construction. These differences can significantly impact equipment selection, especially when considering factors like material type, desired output size, and gradation. For instance, hard materials often require more robust jaw crusher machines and high-quality crusher parts. Throughout this blog, we will look at several types of jaw crushers, including Blake, Dodge, PE Universal, and Mobile jaw crushers, as well as the role of the gyratory crusher in the industry. Additionally, we will discuss the importance of wear resistant steel plates and the various jaw crusher parts that contribute to the efficiency and durability of these machines.

Key Takeaways

- Understanding the differences between jaw crusher types helps in selecting the right equipment for mining and construction projects.

- The Blake Jaw Crusher is known for its efficiency and durability, making it ideal for primary crushing tasks in various industries.

- The Dodge Jaw Crusher offers a more uniform output size but has a lower capacity, making it suitable for niche applications.

- The PE Universal Jaw Crusher combines advanced technology with high efficiency, making it versatile for both small and large operations.

- Mobile jaw crushers provide flexibility by allowing on-site crushing, reducing transportation costs and supporting sustainable practices.

Blake Jaw Crusher

The Blake Jaw Crusher is a significant player in the world of crushing machinery. It was invented by Eli Whitney Blake in 1858. His motivation stemmed from the need for a more efficient method of crushing stone for road construction. With a background in civil and mechanical engineering, Blake designed a machine that mechanized the labor-intensive process of stone crushing. This innovation marked the beginning of a new era in mining and construction.

The Blake Jaw Crusher became the first successful mechanical rock breaker. Its toggle linkage mechanism set a standard for jaw crushers, making it a cornerstone in the history of these machines. The design allows for a larger feed size and higher capacity, making it ideal for primary crushing tasks.

Key Mechanical Features

The Blake Jaw Crusher has several mechanical features that distinguish it from other types:

- The pivot of the swing jaw is located at the top of the machine.

- This design enables a larger feed size and higher capacity.

- The swing jaw’s motion is predominantly vertical, enhancing compression action for efficient material reduction.

These features make the Blake Jaw Crusher particularly effective in various industrial applications. It is commonly used in:

- Aggregates

- C&D Recycling

- Concrete

- Frac Sand

- Mining

In these industries, the Blake Jaw Crusher functions by crushing material between a moving and a stationary piece of steel, ensuring effective size reduction.

Advantages and Disadvantages

Like any machine, the Blake Jaw Crusher has its pros and cons. Here’s a quick look:

| Advantages | Disadvantages |

|---|---|

| Efficient Size Reduction | Size Limitation |

| Simple Design | Maintenance Requirements |

| Versatility | Inefficient at Fine Crushing |

| Durability | Energy Consumption |

| Low Operational Costs | Noise and Dust |

| N/A | Limited Mobility |

| N/A | Uniformity of Product |

Overall, the Blake Jaw Crusher stands out for its efficiency and durability. However, users should consider its limitations, especially regarding size and maintenance.

Dodge Jaw Crusher

The Dodge Jaw Crusher is another important type of jaw crusher. It has a unique design that sets it apart from others. Invented in the early 19th century, this crusher features a bottom pivot point for the swing jaw. This design leads to some distinct advantages and disadvantages.

Key Design Features

One of the main differences between the Dodge Jaw Crusher and other types lies in its swing jaw pivot. In the Dodge design, the pivot is located at the bottom. This contrasts with the Blake Jaw Crusher, where the pivot is at the top. The bottom pivot allows for a more tapered crushing chamber, which can lead to a more uniform output size. Here’s a quick comparison of the Dodge Jaw Crusher with other jaw crushers:

| Feature | Dodge Jaw Crusher | Other Jaw Crushers |

|---|---|---|

| Swing Jaw Pivot | Bottom pivot | Top pivot |

| Crushing Chamber | Tapered | Varies (usually more uniform) |

| Output Size Uniformity | More uniform output size | Varies |

| Capacity | Lower capacity due to design limitations | Generally higher capacity |

| Application | Niche applications, lab-scale crushing | Broader industrial applications |

Advantages and Disadvantages

The Dodge Jaw Crusher has its own set of pros and cons. On the positive side, it offers a more uniform output size, which can be beneficial for specific applications. However, it typically has a lower capacity compared to other jaw crushers. This limitation can affect its efficiency in larger operations.

Tip: If you plan to use a Dodge Jaw Crusher, consider its application carefully. It works best in niche settings or for laboratory-scale crushing.

Operational Challenges

Like any machine, the Dodge Jaw Crusher faces some operational challenges. Regular maintenance is crucial to prevent failures and extend its service life. Components, especially bearings, are prone to wear. This wear can impact efficiency and lead to downtime. Here are some common challenges associated with the Dodge Jaw Crusher:

- Maintenance Issues: Regular maintenance is crucial to prevent failures and extend service life.

- Wear and Tear of Components: Components, especially bearings, are prone to wear, impacting efficiency and leading to downtime.

- Downtime Impact: Any downtime can halt production, leading to low stock levels and reduced output across operations.

To mitigate these challenges, operators should conduct frequent checks on the jaw crusher. Promptly repairing or replacing defective parts can save time and money. Regularly inspecting and replenishing the lubrication system is also essential for smooth operation.

PE Universal Jaw Crusher

The PE Universal Jaw Crusher is a versatile and widely used machine in the mining and aggregate industries. Its design combines advanced technology with practical features, making it a popular choice for various applications. This type of jaw crusher excels in crushing large pieces of material while maintaining high efficiency.

Key Features

The PE Universal Jaw Crusher stands out due to its unique structural and operational characteristics. Here’s a quick overview of its defining features:

| Feature | Description |

|---|---|

| Advanced crushing process | Utilizes advanced technology for precise internal structure, avoiding blockages and improving efficiency. |

| Energy-saving and high efficiency | Single machine energy savings of 15% to 30%, with higher throughput leading to more effective solutions. |

| High-quality materials | Durable wear parts and reliable mechanical components extend the service life of the equipment. |

| Easy to operate | Improved design enhances operation ease and maintenance convenience, boosting availability and profitability. |

| Reducing operating costs | Focus on high-performance equipment to increase customer profitability. |

These features make the PE Universal Jaw Crusher an excellent choice for both small and large-scale operations.

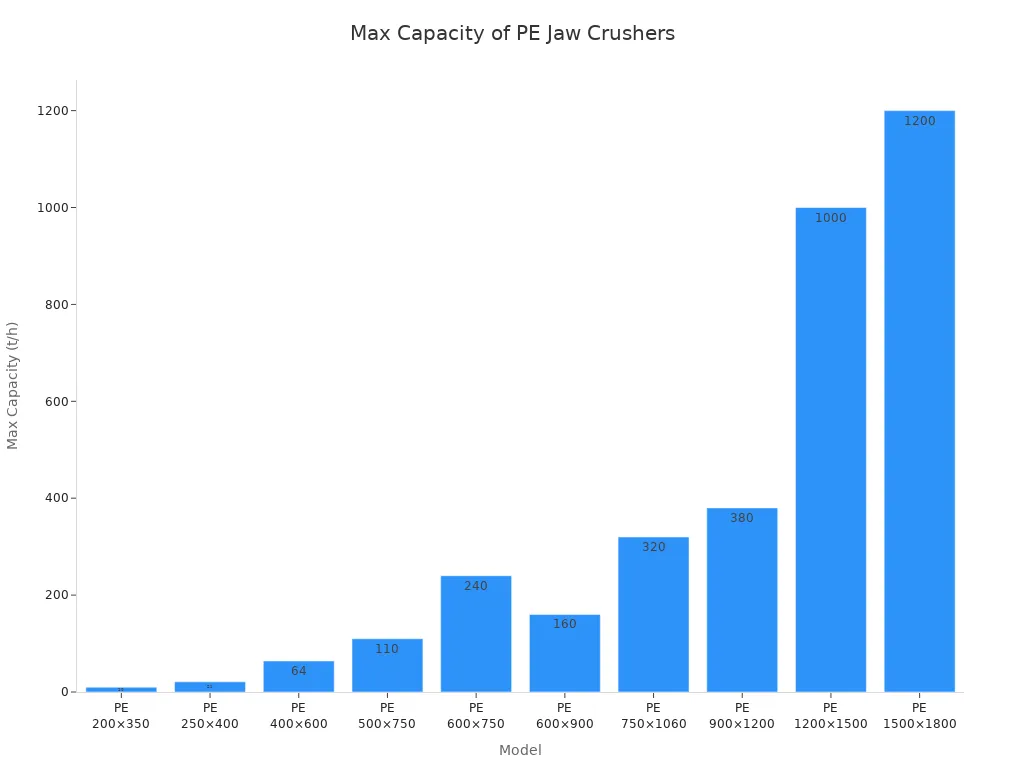

Common Sizes and Capacities

PE Universal Jaw Crushers come in various sizes and capacities to meet different operational needs. Here’s a table showing some of the most common models:

| Model | Feeding opening size (mm) | Max. Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity (t/h) | Power (kw) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 110 | 3470×2876×3330 |

| PE 1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 160-245 | 4850×3220×3680 |

| PE 1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 280-380 | 5160×3660×4248 |

Typical Use Cases

The PE Universal Jaw Crusher finds applications in various sectors. Here’s a look at some of the core applications for different models:

| Model | Core Applications |

|---|---|

| PE-250×400 | Laboratory crushing, small quarries, mobile crushing stations, auxiliary crushing |

| PE-400×600 | Small and medium-sized aggregate production, mines and quarries, construction waste crushing, municipal construction |

| PE-600×900 | Medium-to-large aggregate production, medium-sized mines, large-scale engineering projects, stationary crushing station |

Advantages and Disadvantages

Like any machine, the PE Universal Jaw Crusher has its strengths and weaknesses. Here’s a quick rundown:

- Advantages:

- High crushing efficiency

- Suitable for processing large pieces of material

- Large crushing ratio

- Strong adaptability

- Disadvantages:

- Greater wear when processing extremely hard materials

- Requires frequent maintenance

- Less efficient with fine-grained materials

For specific materials, operators might consider alternatives. For medium-soft materials like limestone, a single toggle jaw crusher may be more suitable. For harder materials such as granite, a double toggle or hydraulic jaw crusher is recommended for better performance.

Mobile Jaw Crusher

Mobile jaw crushers have revolutionized the way construction and demolition projects handle materials. These machines offer flexibility and efficiency, allowing operators to crush materials on-site rather than transporting them to a stationary plant. This capability not only saves time but also reduces transportation costs significantly.

Key Features and Technological Advancements

Mobile jaw crushers come equipped with several advanced features that enhance their performance. Here are some notable technological advancements:

- Remote operation without on-site personnel.

- Centralized management of multiple sites.

- Automation through cloud data analysis for optimization.

- Enhanced material flow and stockpiling capabilities.

- High capacity processing with efficient pre-screening.

- Real-time data collection on operational parameters.

- Predictive maintenance to reduce unexpected failures.

- Improvements in material flow and crushing chamber geometry.

These features make mobile jaw crushers a popular choice for various applications, especially in construction and demolition projects.

Common Applications

Mobile jaw crushers excel in breaking down large chunks of concrete and rock into smaller, reusable sizes. Here are some common applications:

- They simplify the management of demolition debris, making it easier to transport and recycle.

- Crushing on-site allows contractors to save on material costs and potentially sell crushed material as an additional revenue stream.

- Portable jaw crushers can be moved easily on a wheeled chassis, making them ideal for small and midsize projects.

- On-site processing leads to significant savings in demolition disposal and aggregate purchasing costs.

By recycling construction debris such as concrete, bricks, and asphalt into reusable aggregates, mobile jaw crushers support sustainable building practices. They help reduce disposal costs and can cut transportation and disposal costs by up to 40%.

Production Capacities and Mobility

Leading mobile jaw crusher models offer impressive production capacities and mobility features. Here’s a quick overview:

- Production Capacity: Ranges from 30-500 TPH depending on the model.

- Engine Power: Diesel engines from 110-400 kW.

- Undercarriage: Options for tracked or wheeled configurations.

| Feature | Specification |

|---|---|

| Feed opening | 1,200 x 750 mm (47 x 29 in.) |

| Max. feed size | 650 mm (26 in.) |

| Capacity | 400 mtph (440 stph) |

| Transport length | 14.2 m (46.4 ft) |

| Transport width | 2.9 m (9.4 ft) |

| Transport height | 3.4 m (11.3 ft) |

| Weight | 50,000 kg (110,231 lb) |

These specifications highlight the efficiency and versatility of mobile jaw crushers in various operational settings.

Advantages and Disadvantages

Mobile jaw crushers come with their own set of advantages and disadvantages compared to stationary types. Here’s a quick comparison:

| Mobile Crusher | Stationary Crusher |

|---|---|

| Moveable between working sites | Cannot move easily once installed |

| Compact and integrated structure | Large and heavy structure |

| Multiple applications | Limited application |

| Higher in cost | Cost-effective |

| Requires more maintenance | Requires less maintenance |

| Easy to install | Difficult to install |

Advantages of Mobile Crushers:

- Mobility reduces transportation costs.

- Quick setup for temporary projects.

- Space-saving due to integrated systems.

- Reduced environmental impact by processing materials on-site.

- Cost-efficient as it requires less infrastructure.

Disadvantages of Mobile Crushers:

- Generally lower production capacity.

- Limited customization options.

Mobile crushing plants can significantly reduce material transportation costs by processing materials on-site. However, the initial investment for mobile crushers is generally higher, and maintenance costs can also be more substantial compared to stationary plants.

Comparison of Jaw Crusher Types

When choosing a jaw crusher, understanding the differences in performance, cost-effectiveness, and maintenance requirements is crucial. Each type of jaw crusher has unique characteristics that can impact its suitability for specific applications.

Performance

Performance metrics help compare jaw crushers effectively. Here’s a quick look at some key parameters:

| Parameter | Details/Values |

|---|---|

| Maximum Reduction Ratio | 8:1 (compression crushing) |

| Typical Use | Primary crusher |

| Jaw Crusher Naming | Numbers like 3042 mean 30″ wide, 42″ tall |

| Allowable Top Size | About 80% of width (e.g., 24″ for 30″ wide) |

| Closed Side Setting (CSS) | Adjustable; minimum ~3″ for 24″ top size |

| Efficiency | 80-85% (output under CSS size) |

| Output Gradation | 80-85% under CSS; rest between 3″-6″ |

| Capacity Determinant | Width of the jaw |

Different jaw crushers, like Blake and Dodge, also vary in throughput rates and reduction ratios. For instance, the Blake design typically offers a higher reduction ratio, while the Dodge model yields more fines and less oversize product.

Cost-Effectiveness

Cost is always a consideration. Here’s how the main jaw crusher types stack up:

| Application Type | Crusher Size/Capacity | Typical Purchase Price Range | Operating Costs | Maintenance Costs |

|---|---|---|---|---|

| Mining and Heavy-Duty | 500-1500 TPH | $$$$ | High | Moderate to High |

| Aggregate Production | 250-1000 TPH | $$$ | Moderate | Moderate |

| Small-Scale Construction | 50-300 TPH | $$ | Low | Low |

Investing in a jaw crusher machine can be significant, but the long-term benefits often outweigh the initial costs.

Maintenance Requirements

Regular maintenance keeps jaw crushers running smoothly. Here are some common tasks:

- Check jaw plates: Ensure tooth peak to tooth valley match and inspect for wear.

- Tighten bolts/nuts: Regularly check to prevent loosening during operation.

- Inspect jaw surface: Look for flatness, holes, or cracks; adjust or replace as necessary.

- Replace jaw plate: If over 80% worn, replace to maintain performance.

- Clear discharge port: Ensure it is not blocked for unobstructed operation.

- Check V-belt: Tighten if loose to prevent slippage.

- Inspect eccentric shaft: Reinstall or replace bush if loose.

- Correct flywheel wedge: Adjust if position is offset.

The average lifespan of a jaw crusher typically ranges from 5 to 15 years, depending on the operating conditions. In high-load environments, a jaw crusher may last around 6 years, while in less demanding settings, it can extend up to 18 years.

By understanding these factors, operators can make informed decisions when selecting a jaw crusher that best fits their needs.

In summary, understanding the key differences between jaw crusher types is crucial for making informed decisions. Each type, whether it’s the Blake, Dodge, PE Universal, or Mobile jaw crusher, serves unique purposes and has distinct advantages.

When selecting a jaw crusher machine, consider factors like crushing capacity, feed size, and the characteristics of the material. For instance, hard and abrasive materials require robust machines with wear-resistant features.

Remember, choosing the right jaw crusher can significantly impact operational efficiency and cost-effectiveness. Neglecting this choice may lead to excessive wear on jaw plates, uneven particle sizes, and increased operational costs.

By evaluating your specific needs and the material characteristics, you can ensure optimal performance and longevity of your equipment.

FAQ

What is the main purpose of a jaw crusher?

Jaw crushers primarily crush large rocks into smaller pieces. They are essential in mining, construction, and recycling industries for breaking down materials like concrete, granite, and limestone.

How do I choose the right jaw crusher type?

Consider factors like material type, desired output size, and production capacity. Each jaw crusher type has unique features that suit different applications, so assess your specific needs carefully.

What maintenance does a jaw crusher require?

Regular maintenance includes checking jaw plates, tightening bolts, and inspecting the lubrication system. Operators should also replace worn parts promptly to ensure optimal performance and longevity.

Can I use a jaw crusher for recycling materials?

Absolutely! Jaw crushers are effective for recycling materials like concrete and asphalt. They break down debris into reusable aggregates, supporting sustainable construction practices.

How long does a jaw crusher typically last?

A jaw crusher can last between 5 to 15 years, depending on operating conditions. Regular maintenance and proper usage can extend its lifespan significantly.

Post time: Oct-09-2025